Would you like to buy gear-shaving and gear-finishing tools? You have to explore and find the best manufacturers in the industry offering it for you with top quality. Always purchasing the cutters and tools with the best quality and efficient working can work for a long time. The manufacturing experts can offer it to you at an affordable rate. Before you buy the gear shaving cutter, you must understand the cost and then buy it. Then, you have to buy the gear finishing tools from the well-experienced and trained manufacturers in the industry.

What is a gear-saving cutting?

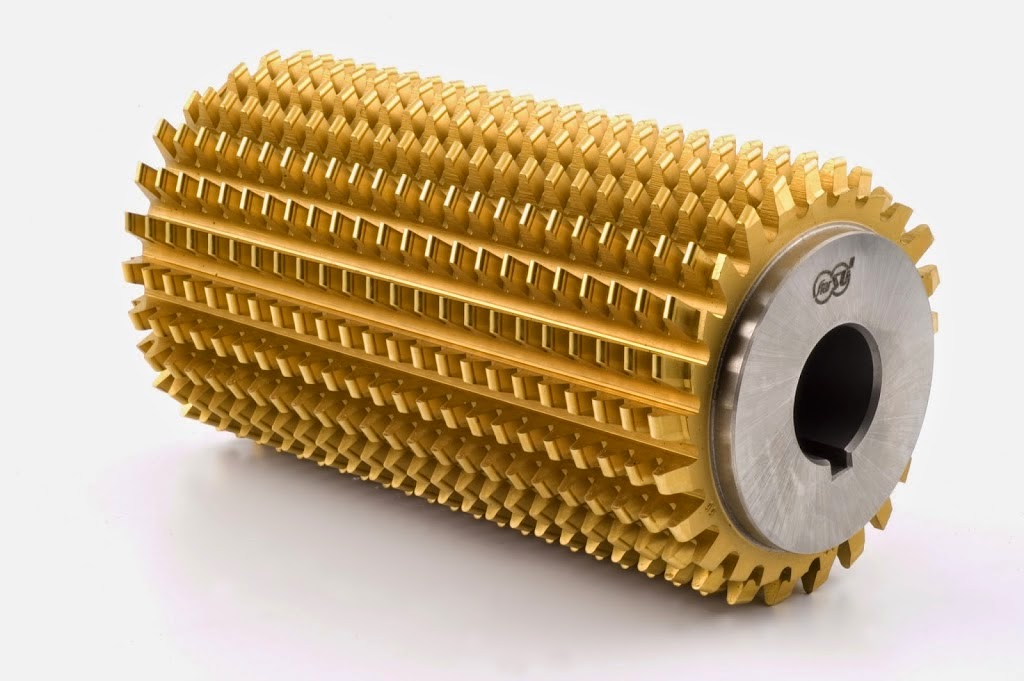

A gear shaving cutter is a tool that can remove the trace number of metals from the gear teeth. It helps offer accurate working surfaces. The gear shaving process aims to safeguard errors in the helical angle, the profile of a gear tooth, the gear index and the eccentricity of the greats. The gear-shaving cutter is mainly designed to match the finishing requirements of the practical working gear. The gear shaving cutter has more types like transverse cutters, plunge cutters, diagonal cutters, underpass cutters, internal and external cutters and underground shaving cutters.

Benefits of using the gear shaving cutters and its cost:

The advantage of using the gear-shaving cutter is its high degree of accuracy. It is used in producing the finest quality of gears. They are responsible for determining the degree of accuracy of the products. This cutter has a comparatively lower cost and offers the best output ratio. The gear shaving cutter price is less than you think, and it is feasible for you to buy without hesitation. Whenever you are ready to buy the gear shaving cutters, you must look at the cost and then buy it. So, always look at the cost of the gear shaving cutters for shopping in the best online stores.

What are gear finishing cutters and their purpose?

Gear finishing cutters are the type of cutters that are useful in providing the finishing process of the gear. It is used in the gear manufacturing process, and the primary purpose is to improve the gear’s dimensional accuracy and surface finish after machining. The finishing process of the gears that are not heat treated includes shaving and burnishing. The finishing process using the gear finishing cutters is applied to the hardened gears such as grinding, lapping and honing.

How to choose the best manufacturers to get gear finishing cutters?

It is better to search and select the industry’s best gear finishing tools manufacturers for buying the gear finishing cutters. Here are some of the things that you should remember at the time of choosing the manufacturers. They are to look at their trustworthiness, the quality of cutters they offer, experience, knowledge, practice in the manufacturing field, interest, communication, certification, and so on. You must also keep an eye on the type of new technologies and the process they include when manufacturing the gear finishing cutters or tools. So, these are the best things you should remember when selecting the gear finishing cutters.

Conclusion:

So, this guide helps you understand the gear shaving cutters and finishing tools. You can also learn about the shaving cutters’ cost and how to choose the best gear-finishing tool manufacturers.