In today’s rapidly evolving industrial landscape, the pursuit of operational efficiency has become paramount. Industries spanning from power generation to HVAC (heating, ventilation, and air conditioning) are constantly seeking innovative solutions to optimize performance, reduce downtime, and cut operational costs. One such solution that has gained significant traction in recent years is automatic tube cleaning systems.

Automatic Tube Cleaning System Market Outlook

The global automatic tube cleaning system market size is poised for substantial growth in the forecast period of 2024-2032. With a projected compound annual growth rate (CAGR) of 4.5%, this market presents lucrative opportunities for businesses operating in the heating, ventilation, and air conditioning sectors, among others. As industries continue to prioritize energy efficiency and sustainability, the adoption of automatic tube cleaning systems is expected to witness a notable upsurge.

Automatic Tube Cleaning System Market Overview

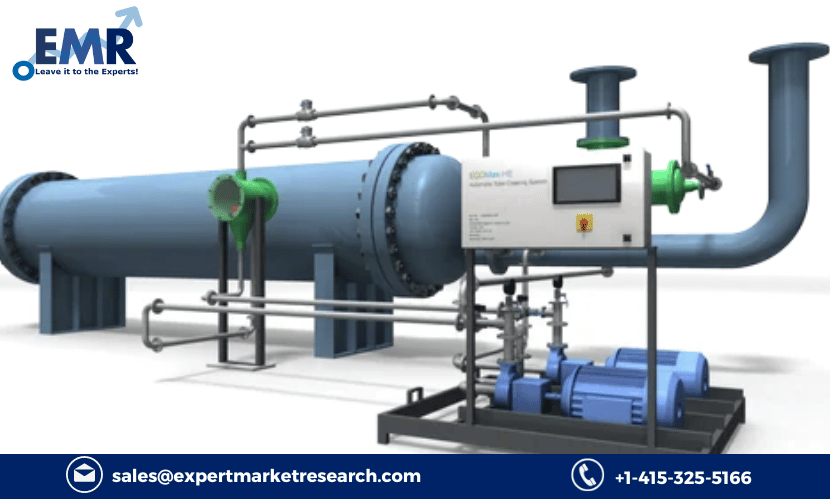

Automatic tube cleaning systems are innovative technologies designed to mitigate fouling-related issues in heat exchangers, condensers, and other critical equipment. By preventing the accumulation of deposits such as scale, biofilm, and fouling, these systems ensure optimal heat transfer efficiency and reduce the need for manual cleaning and maintenance. The market for automatic tube cleaning systems is driven by the growing demand for energy-efficient solutions and the increasing emphasis on proactive maintenance strategies.

Automatic tube cleaning systems are innovative solutions designed to prevent the build-up of deposits such as scale, biofilm, and fouling inside heat exchanger tubes, condensers, and other critical equipment. These systems utilize various technologies, including mechanical scrapers, brushes, and chemical injection, to maintain optimal heat transfer efficiency and reduce energy consumption.

Automatic Tube Cleaning System Market Size and Share

According to market research, the global automatic tube cleaning system market size is expected to reach new heights in the forecast period. With a CAGR of 4.5%, the market is projected to witness substantial growth, driven by the rising adoption of automatic tube cleaning systems across various industries. As businesses recognize the value of optimizing heat transfer processes and minimizing downtime, the demand for these innovative solutions is on the rise.

Get a Free Sample Report with Table of Contents@

https://www.expertmarketresearch.com/reports/automatic-tube-cleaning-system-market/requestsample

Automatic Tube Cleaning System Market Trends

Several key trends are shaping the global automatic tube cleaning system market landscape. One notable trend is the integration of smart monitoring and control capabilities into automatic tube cleaning systems. By leveraging real-time data analytics and predictive maintenance algorithms, operators can optimize cleaning schedules, detect potential equipment failures, and proactively address performance issues, thereby maximizing productivity and minimizing operational risks. Additionally, advancements in sensor technology and remote monitoring capabilities are enhancing the efficiency and effectiveness of automatic tube cleaning systems, driving market growth.

-

Emphasis on Energy Efficiency: Energy efficiency has emerged as a primary concern for industries across the globe. With rising energy costs and increasing environmental regulations, businesses are prioritizing solutions that help minimize energy consumption. Automatic tube cleaning systems play a crucial role in improving energy efficiency by preventing fouling-related losses and maintaining optimal heat transfer performance. As a result, there is a growing demand for these systems among industries seeking to reduce their carbon footprint and achieve sustainability goals.

-

Integration of Smart Technologies: Advancements in sensor technology, data analytics, and IoT (Internet of Things) have paved the way for the integration of smart features into automatic tube cleaning systems. These systems can now monitor equipment performance in real-time, analyze operational data, and adjust cleaning schedules dynamically based on actual fouling conditions. By leveraging predictive maintenance algorithms, operators can detect potential issues before they escalate, thereby minimizing downtime and maximizing equipment reliability.

-

Adoption of Remote Monitoring Solutions: Remote monitoring capabilities are becoming increasingly prevalent in automatic tube cleaning systems. This allows operators to monitor system performance and receive alerts remotely, enabling proactive maintenance interventions regardless of location. Remote monitoring solutions offer greater flexibility and convenience, especially for industries with distributed operations or limited onsite personnel. Additionally, remote diagnostics enable faster troubleshooting and problem resolution, leading to improved operational efficiency and reduced downtime.

-

Customization and Modular Design: With industries operating in diverse environments and facing unique operational challenges, there is a growing demand for customizable and modular automatic tube cleaning solutions. Manufacturers are offering a range of options to accommodate different tube sizes, materials, and fouling characteristics. Modular designs allow for scalability and flexibility, enabling users to customize their systems based on specific requirements and budget constraints. This trend towards customization ensures that automatic tube cleaning systems can address the varying needs of different industries and applications effectively.

-

Focus on Water Conservation: Water conservation is gaining prominence as a critical sustainability initiative across industries. Automatic tube cleaning systems offer a sustainable solution for reducing water consumption in cooling applications by minimizing the need for manual cleaning and chemical treatments. By continuously removing deposits from heat exchanger tubes, these systems help maintain optimal heat transfer efficiency without the use of excessive water or chemicals. As water scarcity concerns continue to grow, the adoption of automatic tube cleaning systems is expected to increase, particularly in water-intensive industries such as power generation and HVAC.

-

Rise of Condition-Based Maintenance: Condition-based maintenance (CBM) strategies are gaining traction as a proactive approach to equipment maintenance and reliability. Automatic tube cleaning systems support CBM initiatives by providing real-time data on fouling levels, flow rates, and heat transfer performance. By analyzing this data, operators can identify trends and patterns indicative of potential issues, allowing them to intervene proactively and prevent costly equipment failures. The shift towards CBM reduces reliance on reactive maintenance practices and helps optimize maintenance schedules, leading to improved equipment uptime and longevity.

Industry Segmentation

The automatic tube cleaning system market can be segmented based on application, end-user industry, and region. In terms of application, these systems find extensive usage in power generation, HVAC, oil and gas, chemical processing, and food and beverage manufacturing, among other sectors. End-user industries such as power plants, refineries, petrochemical plants, and food processing facilities are increasingly adopting automatic tube cleaning systems to improve operational efficiency and reduce maintenance costs.

The market can be divided based on type, application, industry, and region.

Market Breakup by Type

- Automatic Ball Tube Cleaning System

- Automatic Brush Tube Cleaning System

Market Breakup by Application

- Condenser

- Chiller

- Boiler

- Others

Market Breakup by Industry

- Power Generation

- Oil and Gas

- Commercial Space

- Hospitality

- Others

Market Breakup by Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Forecast Period 2024-2032

Over the forecast period of 2024-2032, the global automatic tube cleaning system market is expected to witness significant growth. As industries continue to prioritize energy efficiency, regulatory compliance, and operational optimization, the demand for automatic tube cleaning systems is poised to escalate. With advancements in technology and increasing awareness about the benefits of these systems, market players are poised to capitalize on emerging opportunities and drive innovation in the automatic tube cleaning segment.

Competitive Landscape

The global automatic tube cleaning system market is characterized by intense competition among key players. Leading companies are focusing on research and development initiatives to introduce advanced solutions that cater to the evolving needs of end-users. Additionally, strategic partnerships, collaborations, and mergers and acquisitions are prevalent in the market as companies seek to expand their product portfolios and enhance their market presence.

- Trane Technologies plc

- Innovas Technologies, LLC

- Ovivo, Inc.

Media Contact

Company Name: Claight Corporation

Contact Person: Christopher, Business Consultant

Email: [email protected]

Toll Free Number: US +1-415-325-5166 | UK +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com