Caterpillar Inc. is a significant producer of heavy equipment, including compactors. Their compactors commonly work by utilizing hydraulic systems to apply force to the waste materials, compressing them into smaller volumes. These machines frequently highlight a large, heavy drum or plate that applies strain to the waste, compacting it.

Caterpillar compactors help in different businesses and applications, including waste administration, construction, street building, and landfill tasks. In waste management, Caterpillar compactors assume an essential role in lessening the volume of waste materials, making them easier to deal with, transport, and discard.

These machines come in various sizes and arrangements to suit different waste administration needs, from private ventures to enormous-scale activities.

Overall, Caterpillar compactors add to more proficient waste administration work, helping organizations and districts save time, cash, and assets while decreasing their natural impression.

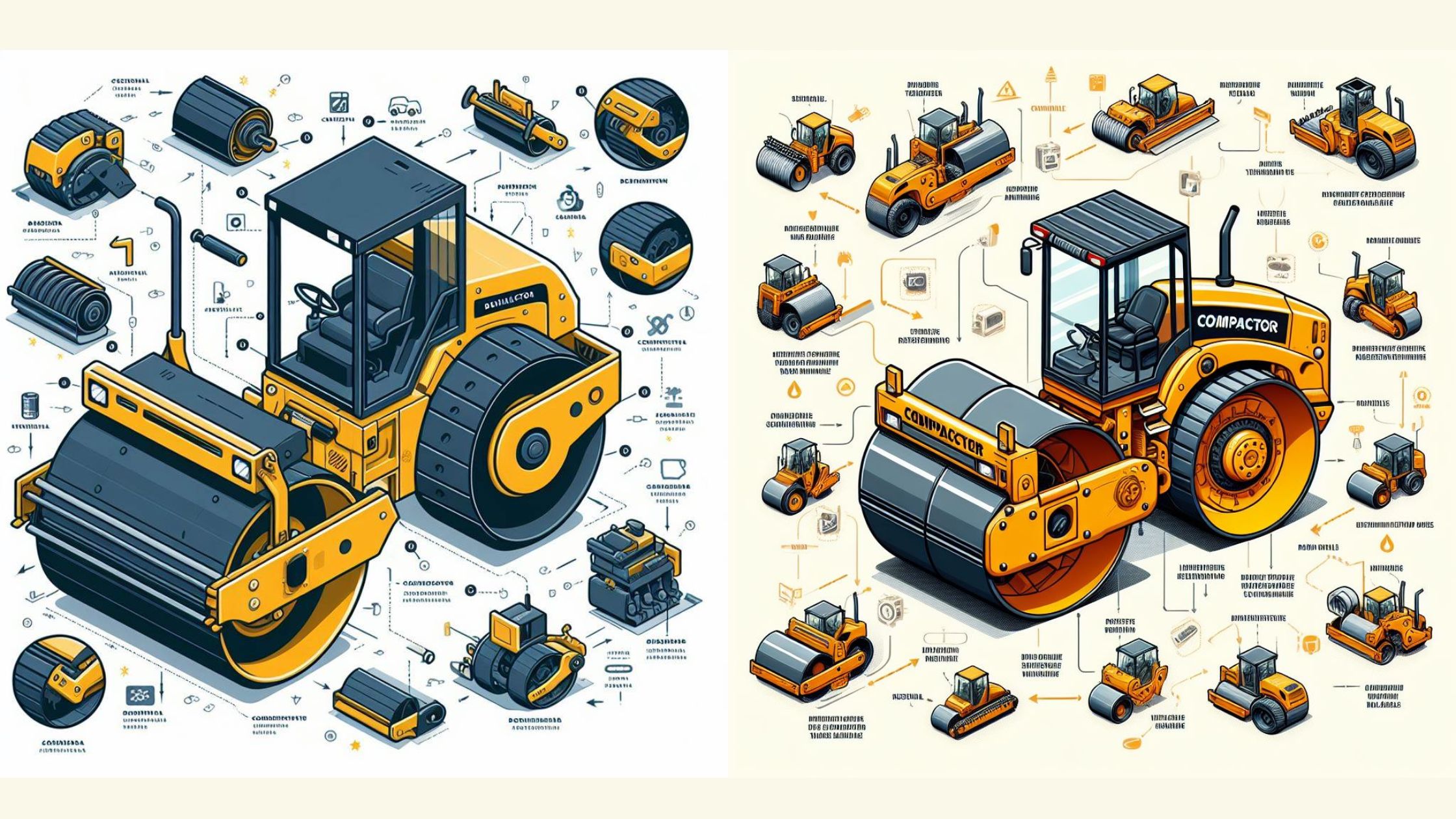

Compactor Machine: How do compactor machines work?

Compactor vehicle ordinarily help in waste management, development, and reuse businesses. Here is an overall outline of how compactor machines work:

Loading:

The material to be compacted is loaded into the compactor. Contingent upon the compactor, this might be done manually or with the assistance of a transport line or other mechanical means.

Compression:

When the material is stacked, the compactor applies strain to pack it. It is normally done using a hydraulic system, which uses a hydraulic chamber to apply power to the material. The pressure is steadily expanded until the ideal degree of compaction is achieved.

Ejection:

When the material is packed, it is catapulted from the compactor. It is often done by utilizing a mechanical framework, for example, a smash or a transport line, that moves the compact material out of the compactor.

Capacity or removal:

The compacted material is put away or discarded, contingent upon the expected use. Now and again, the compactor material can be handled differently, such as reusing it.

Compactor Vehicle: Types

Compactor machines pack different materials, including waste, soil, and development materials. There are a few sorts of compactor machines, including:

Plate compactors

Plate compactors are small, lightweight machines used to minimize soil and blacktop in small regions, like driveways and parking areas. They consist of a heavy steel plate that vibrates quickly to pack the material.

Jumping jack compactors

Jumping jack compactors are like plate compactors, yet they utilize an alternate system to reduce the material. They have a small foot that quickly bounces all over, packing the material.

Roller compactors

Roller compactors are bigger machines that use at least one roller to pack the material. They help in street development and can be either self-move or tow behind a vehicle.

Pneumatic compactors

Pneumatic compactors use air pressure to pack the material. They ordinarily help in developing landing strips and other enormous, open spaces.

Vibratory soil compactors

Vibratory soil compactors utilize a huge vibrating plate to minimize soil and different materials. They help in street development and can be either self-push behind a vehicle.

Landfill compactors

These machines help in landfills and also for compact waste materials. They are commonly huge and weighty and use a mix of weight and vibration to pack and reduce waste.

Picking a Compactor Machine: Factors to Consider

Type of waste: The kind of waste that should be compacted ought to be thought about while picking a compactor machine. Various sorts of waste require multiple types of gadgets.

Space accessibility: The size of the space accessible for the machine ought to be thought about when picking a compactor machine. A few gadgets are bigger than others and require more space.

Capacity: The machine’s ability ought to be thought about when picking a compactor machine. Choosing a gadget that can deal with the amount of waste that should be compact is urgent.

Productivity: The machine’s effectiveness ought to be thought about when picking a compactor machine. A more effective machine will set aside time and cash over the long haul.

Efficiency: The machine’s sturdiness ought to be thought about when picking a compactor machine. A strong machine will endure longer and require less upkeep.

Compactor Machine: Uses

Waste Management: Compactor machines are normally utilized in waste management to diminish the volume of strong waste. They help landfills pack squander, lessening the space required for removal.

Reusing: Compactor machines additionally help in reusing offices to pack recyclable materials, like cardboard, plastic, and aluminium jars. It decreases how much space is needed for capacity and transportation.

Development: Compactor machines pack soil, rock, and different materials utilized for development. It makes a steady starting point for structures, streets, and other designs.

Farming: Compactor machines pack feed and different harvests into bundles for capacity and transport. It makes it more straightforward to deal with and transport huge amounts of yield.

Producing: Compactor machines pack salvaged material, plastic, and different materials for reusing or removal.

Compactor Machine: Advantages

Here are a few advantages to utilizing compactors:

Space-saving: Compactors compress the materials and diminish their volume by up to 75%, saving space nearby and in transportation.

Cost-effective: By reducing the volume of materials, compactors can decrease the recurrence of waste expulsion, bringing about lower costs.

Improved hygiene and security: Compactors can diminish the risk of flames, bug pervasions, and scents, making the climate cleaner and more secure.

Environment advantages: Compactors can assist with diminishing how much waste is in landfills, which is better for the climate.

Expanded effectiveness: Compactors can deal with huge amounts of materials rapidly and proficiently, increasing efficiency and decreasing work costs.

Adaptability: There are various kinds of compactors for different materials, like junk, soil, and cement, making them flexible instruments for other ventures.