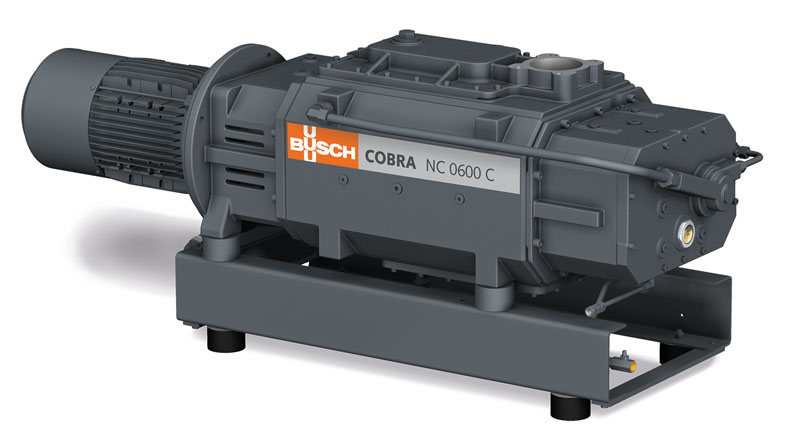

Dry Screw Vacuum Pump stand as a testament to technological innovation, reshaping industrial processes with their unparalleled efficiency and reliability. In this comprehensive exploration, we’ll delve deeper into the world of dry screw vacuum pumps, uncovering their inner workings, diverse applications, notable benefits, and essential considerations for selecting the perfect pump to power your operations.

Understanding Dry Screw Vacuum Pumps: A Technological Marvel

At the heart of every dry screw vacuum pump lies a pair of intermeshing screws that rotate in synchrony to compress gas along their length. This innovative design eliminates the need for oil lubrication, distinguishing dry screw pumps from traditional oil-sealed counterparts. By operating without oil, these pumps offer a contamination-free solution ideal for industries where product purity is paramount.

Applications Across Industries: Powering Progress

The versatility of dry screw vacuum pumps extends across a multitude of industries, serving as the backbone of critical processes:

Chemical and Pharmaceutical: In chemical processing and pharmaceutical manufacturing, dry screw vacuum pumps play a pivotal role in tasks such as solvent recovery, vacuum distillation, and crystallization. Their oil-free operation ensures product integrity and prevents contamination, meeting the stringent standards of these industries.

Food and Beverage: Within the food and beverage sector, dry screw vacuum pumps find applications in vacuum packaging, freeze drying, and deaeration processes. Their hygienic design and oil-free operation contribute to maintaining food safety and quality standards.

Environmental Remediation: Dry screw vacuum pumps are instrumental in environmental remediation efforts, including soil and groundwater remediation, vapor extraction, and landfill gas recovery. Their robust construction and reliable performance make them well-suited for handling challenging environmental conditions.

Semiconductor Manufacturing: Semiconductor fabrication facilities rely on dry screw vacuum pumps for processes such as plasma etching, chemical vapor deposition (CVD), and wafer handling. The absence of oil ensures the purity of semiconductor materials, facilitating the production of high-quality electronic components.

Benefits of Dry Screw Vacuum Pumps: Efficiency Redefined

Dry screw vacuum pumps offer a myriad of advantages over traditional vacuum pump technologies:

Oil-Free Operation: With no oil lubrication involved, dry screw vacuum pumps eliminate the risk of oil contamination in vacuum processes, safeguarding product purity and integrity.

Energy Efficiency: Dry screw vacuum pumps typically consume less energy than oil-sealed pumps, resulting in lower operating costs and reduced environmental impact, aligning with sustainability goals.

Low Maintenance: Featuring fewer moving parts and no oil to change or monitor, dry screw vacuum pumps require minimal maintenance, translating to increased uptime and productivity.

Quiet Operation: Dry screw vacuum pumps operate with minimal noise levels compared to oil-sealed pumps, creating a quieter and more comfortable working environment for operators.

Selecting the Right Dry Screw Vacuum Pump: Key Considerations

When choosing a dry screw vacuum pump for your application, consider the following factors:

Capacity and Vacuum Level: Assess the pump’s capacity and ultimate vacuum level to ensure it meets the requirements of your specific application, balancing performance with efficiency.

Process Compatibility: Verify that the pump’s materials of construction are compatible with the gases and chemicals present in your process to prevent corrosion or contamination, ensuring long-term reliability.

Reliability and Maintenance: Research the manufacturer’s reputation for reliability and the availability of maintenance and support services to minimize downtime and ensure continuous operation, maximizing productivity.

Energy Efficiency: Evaluate the pump’s energy efficiency ratings and compare them with other models to choose the most cost-effective option for your operations, optimizing resource utilization.

Footprint and Installation Requirements: Consider the pump’s size, weight, and installation requirements to ensure it fits seamlessly into your existing infrastructure, minimizing space constraints and installation complexity.

Dry screw vacuum pumps represent a quantum leap in vacuum pump technology, offering unparalleled efficiency, reliability, and performance across a diverse array of industries. By understanding their inner workings, applications, benefits, and key selection considerations, businesses can harness the full potential of these innovative pumps to drive progress and innovation in their operations. Invest time and effort in researching reputable manufacturers and evaluating pump specifications to make an informed decision that aligns with your specific needs and goals. Remember, the right choice of dry screw vacuum pump can unlock new levels of efficiency and productivity, propelling your business towards success in the dynamic landscape of modern industry.