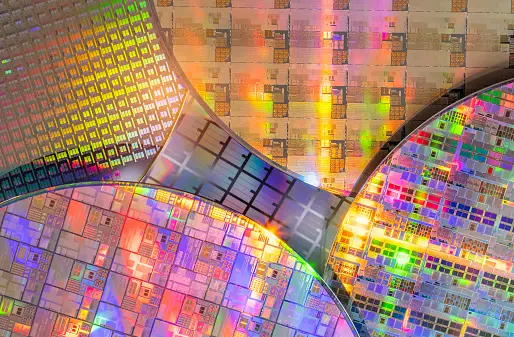

In the vast realm of technology, where innovation knows no limits, there is a crucial element quietly playing a pivotal role in fueling the digital marvels we rely on daily – Silicon Wafers. These ultra-thin slices of crystalline silicon may seem unassuming, yet they are the unsung heroes of semiconductor manufacturing, laying the foundation for our digital world.

Understanding the Significance of Silicon Wafers

Silicon wafers serve as the fundamental components of semiconductor devices, acting as the platform where intricate electronic circuits are fabricated. Originating from highly purified silicon crystals, these wafers undergo a meticulous manufacturing process, resulting in a flat, thin, and flawless surface. The semiconductor industry relies on these wafers for their exceptional electrical properties and uniformity, making them a vital ingredient in the creation of microchips and integrated circuits.

Precision at the Core: Semiconductor fabrication is a domain where precision is not just valued but imperative. With their consistent thickness and high crystalline quality, Silicon wafers provide the ideal foundation for the intricate patterns of transistors and other components that comprise electronic circuits. This level of precision is crucial in ensuring optimal performance and reliability of electronic devices, ranging from smartphones to sophisticated computing systems.

Innovation in Miniaturization: As we marvel at the continual reduction in size of electronic devices, credit must be given to the innovation in semiconductor manufacturing. Silicon wafers facilitate the production of smaller and more efficient microchips, driving the evolution of technology. Thanks to the precision afforded by silicon wafers, the ability to cram more transistors into a limited space has been a catalyst for the ongoing progress we observe in the electronics industry.

The Core of Moore’s Law: Moore’s Law, envisioned by Gordon Moore, co-founder of Intel, foresaw the doubling of transistor density on integrated circuits approximately every two years. This prediction has held true for many years, with silicon wafers playing a crucial role in its realization. The continuous improvement in the quality and production of silicon wafers has enabled the semiconductor industry to keep pace with Moore’s Law, pushing the boundaries of what was once deemed impossible.

The next time you hold a device in your hand, take a moment to appreciate the intricate dance of electrons across the silicon wafer inside and marvel at the relentless spirit of human innovation that makes it all possible. Silicon wafers are not mere components; they are the silent architects of our digital destiny. For further information on Silicon Wafers and their applications, visit www.nanorh.com.